Activated alumina balls are a porous, high surface area form of aluminum oxide that is commonly used as a desiccant or a catalyst in various industrial and commercial applications. They are produced by heating aluminum hydroxide to a high temperature, causing it to lose water molecules and transform into a crystalline form of aluminum oxide.

In addition to their desiccant properties, activated alumina balls are also used as a catalyst in a variety of chemical reactions. The high surface area and porosity of the balls allow for increased contact between the catalyst and reactants, which can lead to improved reaction rates and selectivity.

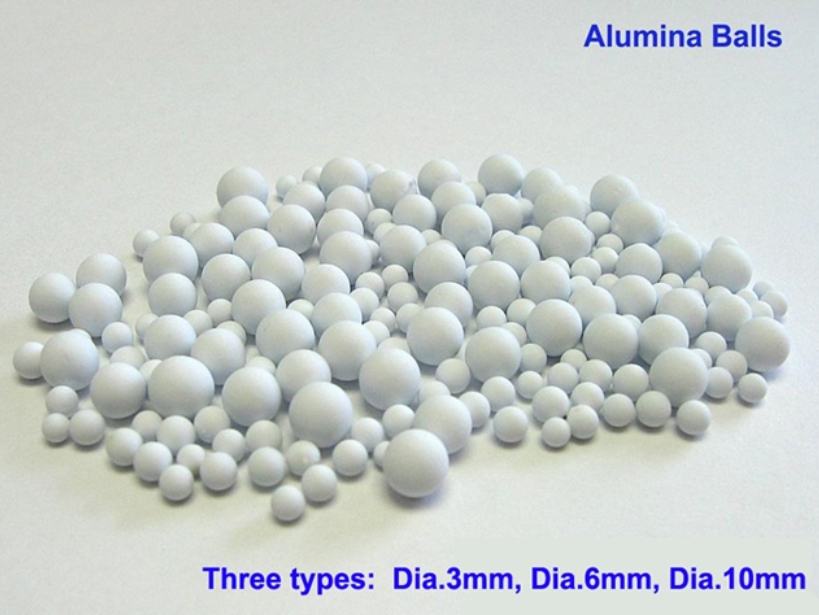

Activated alumina balls are available in various sizes and shapes, including spherical, cylindrical, and crushed forms. They can be reused multiple times by regenerating them through heating or other means to remove absorbed moisture or other contaminants.

Activated alumina balls have several features that make them useful for a variety of industrial and commercial applications. Here are some of their key features:

Overall, the features of activated alumina balls make them a versatile and effective solution for a variety of industrial and commercial applications.

| Partlcle form ::- Spheres | Spheres | ||||

| Particle size ::- 2-5 min and 5-8 mm dia batts. | 1.5 -2.5 mm dia Spheres | ||||

| PHYSICO-CHEM ICAL PROPERTIES | UNIT | SKAA 101 |

SKAA 202 |

Alumina (PE) | |

|---|---|---|---|---|---|

| Physical Appearance | Amorphous fi'hite Granules | ||||

| Equilibrium Water Adsorption Capacity 30 and 60 % RH | %w/w | 20-25 | 14-16 | -- | |

| Surface Area (BES Method) | M2/g | 300-425 | 250-325 | 270-360 | |

| Pore Volume | Cc/g | 0.4—0.5 | 0.3—0.35 | -- | |

| Loss On Ignition (250 — 1000 deg, C) | %w/w | 4.5-8.0 | 4.5-8.0 | 6-9 | |

| Crushing Strength (Active) | Kg. | 9-15 | 9-15 | 4-8 | |

| Attrition Loss on Tumbling | %w/w | 0-0.4 | 0-0.4 | 0-0.4 | |

| Free Moisture (Max) | %w/w | 1.5 | 1.5 | 1.5 | |

| Bulk Density | g/l | 750-850 | 800-950 | 700-870 | |

| Bed crushing Strength | % | 90-99 | 90-99 | -- | |

| Size Tolerance Max (Over size / under size) | % | 5.0 | 5.0 |

Over 7 mesh 5.0 max Over 12 mesh 95 min Under 20 mesh 1.0 max |

|

The industrial application of activated alumina balls is packed in sealed MS drums under heated conditions with adequate sealing arrangements to prevent moisture intrusion during storage and transportation. Standard packaging: 210 Litre drum, 565 x 850 mm in height.

Life:When kept in a packed state, activated Alumina balls have an endless shelf life. However, the active service life would be based on the actual application and plant operating conditions. as well as the customer's use.

Loading:While loading, Activated Alumina Ball doesn't require any particular safety measures or methods. However, before the adsorbent is loaded, the condition of the grid support must be examined, and the vessel must be cleaned of dust and other foreign materials. In order to prevent dusting and attrition, the material should be properly poured through the funnel and chute during the actual loading process. The drums shouldn't be left alone. as moisture would be absorbed by the adsorbent. The adsorbent may need prolonged regeneration at a higher temperature if it was exposed to moisture for an extended period of time during loading or storage.

The product as such is neither inflammable, nor toxic. over all. it is not hazardous- Repeated exposure may irritate skin, eyes and respiratory system. The product gets hot as it is first exposed to atmosphere due to adsorption of moisture.

Regeneration:Before use, the Activated Alumina Ball needs to be regenerated. Between 150 and 180 C are the regeneration temperatures. The temperature of regeneration is higher. The operational cycle time and gas exit dew point are inversely correlated with each other. If high efficiency (dew point better than -50 C) is required, the regeneration temperature must be at least 180 C if the regeneration gas is moist. Regeneration must occur at a higher temperature of 200–250 c. The Activated Alumina Ball from SKAA shouldn't be exposed to temperatures exceeding 350 C regularly if you want it to operate better over a long length of time.

Applications:Feed Air Drying to N2-O2 Process purification using a cryogenic plant Stream by removing contaminants caused by HF (LAB Plant), chloride, and HCI Catalyst for Gas Flow Elimination of residue from polyethylene products. removing colour and heavy metals from PE products.